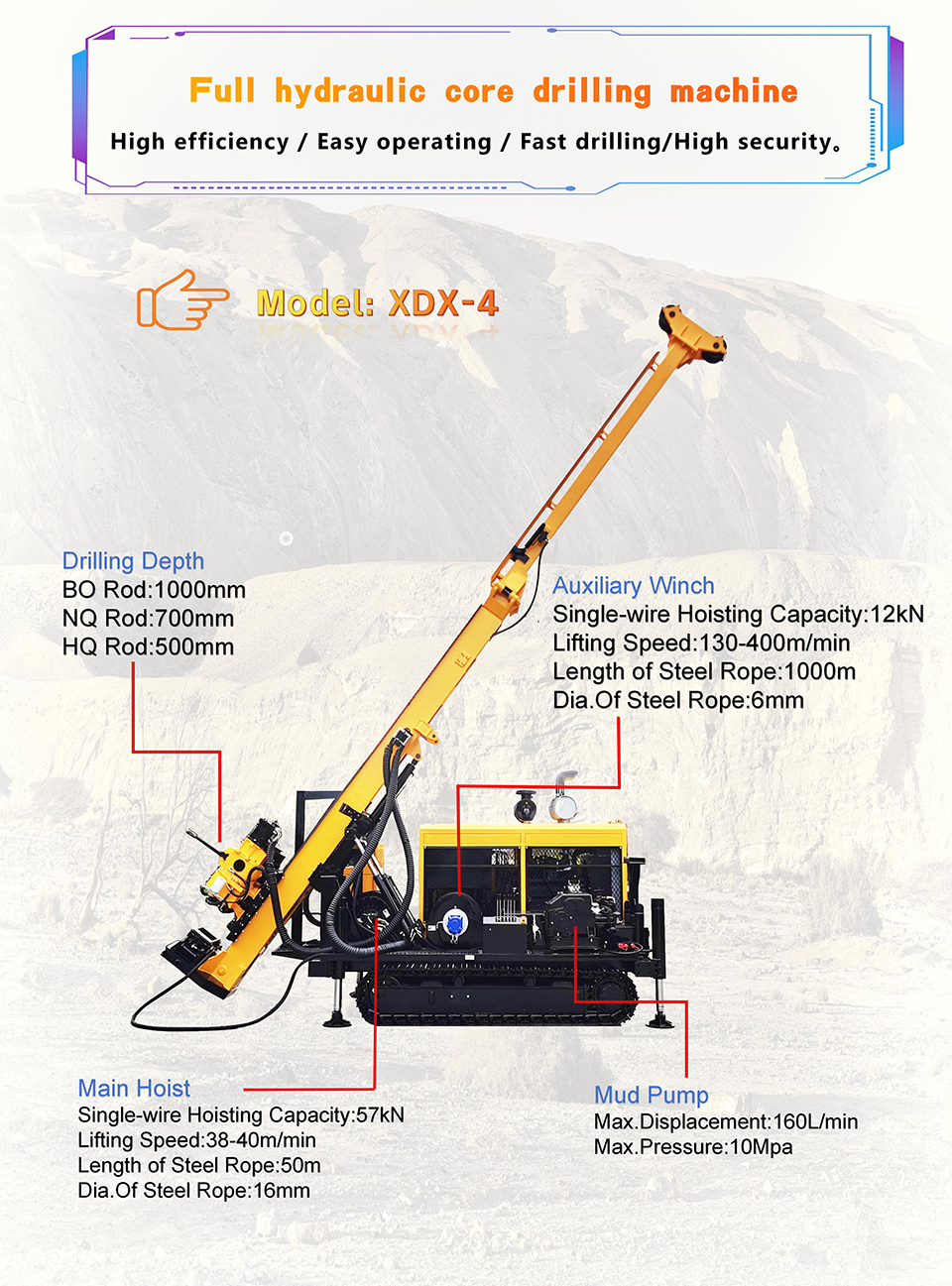

XDX-4 Hydraulic core drilling rig

High Quality Hydraulic Mine Drilling Rig Exploration Core Sample Drilling For Mining

I.Brief Introduction

XDX-4 core drill rig of full hydraulic and rotator adopted the technology of wire-line coring has been the dominant type rig for solid mineral deposits prospecting in developed counties in the world. It is also the developing direction of drilling technique and drilling equipment in China. Under these circumstances, Our company has developed the XDX-4 core drill rig successfully according to the situation of China. This type of drill rig could substitute imported products. It could be applied to exploration and prospecting of geology, metallurgy, coal, petroleum, natural gas, groundwater and other industries.

XDX-4 Hydraulic core drilling rig is equipped with a series motor driving pump. The feeding and lifting of rotator are driven in the structure ofcylinder directly pushing, with a 3.5m(11.5 feet) stroke. The rotation of spindle is driven by a single engine. It has four mechanical shifts of range of speeds, and the speed could be adjusted hydraulicly with stepless change. The rig is simple in structure. It is light and easy for transference; the mast has the functions of sliding and touching ground;the spindle lifted and lowered with hydraulic cylinder; it could be folded for transport and relocation. The spindle hole is in large diameter.

Main parts and auxiliary equipment, including engines, diesel engines, hydraulic pumps,gear reducers,some key valves and hydraulic accessories, are well-known brand products

SO, the failure rate is low and the maintenance is convenient.

We have several models for you to choose from.

They can all meet your different diameters and depths for exploration.

| Model / Item | Unit | XDX-4 | |||

| Drilling Depth | BQ Rod(φ55.6mm) | m | 1200 | ||

| NQ Rod(φ69.9mm) | 900 | ||||

| HQ Rod(φ88.9mm) | 700 | ||||

| Drill Head Capacity | Speed Range | Grade I | r/min | 105-206 | |

| Grade II | 184-361 | ||||

| Grade Ⅲ | 334-656 | ||||

| Grade Ⅳ | 569-1150 | ||||

| Corresponding Torque | Grade I | N.m | 5500-2833 | ||

| Grade II | 3168-1613 | ||||

| Grade Ⅲ | 1743-887 | ||||

| Grade Ⅳ | 1024-521 | ||||

| Max.Rotary Speed | r/min | 1150 | |||

| Max.Torque | N ·m | 5500 | |||

| Hole Diameter of Spindle | mm | 98 | |||

| Max.Lifting Capacity | kN | 150 | |||

| Max.Feeding Power | kN | 60 | |||

| Translational Distance | mm | 350 | |||

| Diesel Engine | Rated Power | kW | 132(Cummins 6BTA5.9-C180) | ||

| Rated Speed | r/min | 2200 | |||

| Hydraulic Pump | Pump 1 | Rated Pressure | MPa | 30 | |

| Max.Flow | L/min | 140 | |||

| Pump2 | Rated Pressure | MPa | 25 | ||

| Max.Flow | L/min | 120 | |||

| Pump3 | Rated Pressure | MPa | 20 | ||

| Max.Flow | L/min | 50 | |||

| Side Pump1 | Rated Pressure | MPa | 16 | ||

| Max.Flow | L/min | 12 | |||

| Side Pump2 | Rated Pressure | MPa | 5 | ||

| Max Flow | L/min | 8 | |||

| Mast | Total Height | m | 9.2 | ||

| Adjusting Angle | ° | 0~90 | |||

| Drilling Angle | ° | 45~90 | |||

| Feeding Stroke | mm | 3500 | |||

| Sliding Distance of Mast | mm | 1100 | |||

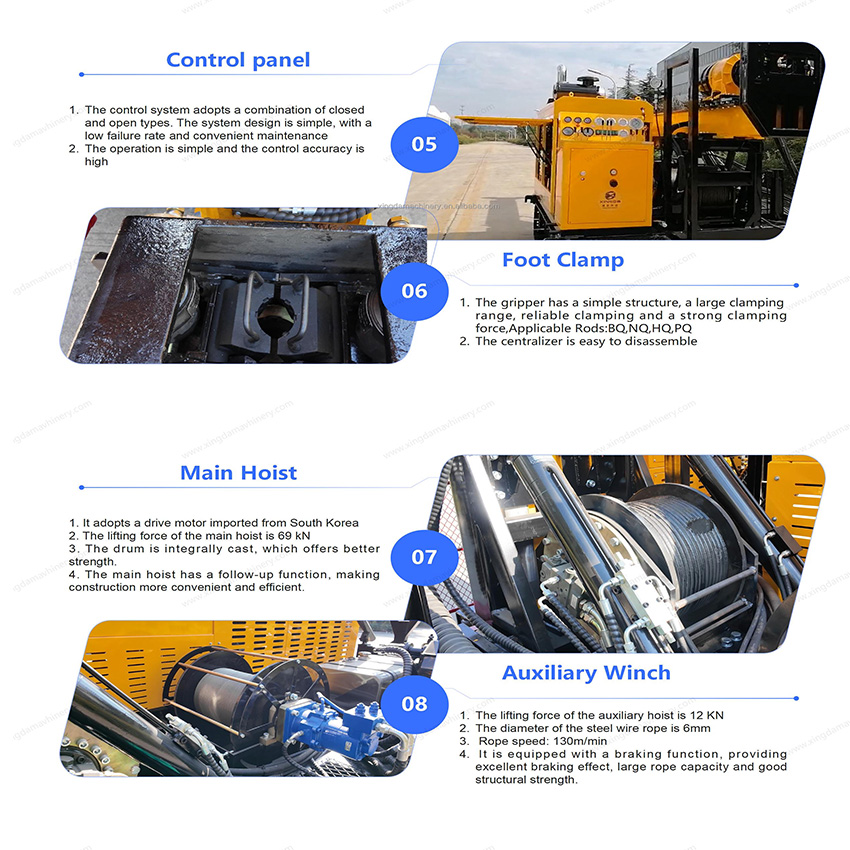

| Main Hoist | Single-wire Hoisting Capacity | kN | 69 | ||

| Lifting Speed | m/min | 40 | |||

| Dia.Of Steel Rope | mm | 16 | |||

| Length of Steel Rope | m | 50 | |||

| Auxiliary Winch | Single-wire Hoisting Capacity | kN | 12 | ||

| Lifting Speed | m/min | 130 | |||

| Dia.Of Steel Rope | mm | 6 | |||

| Length of Steel Rope | m | 1000 | |||

| Mud Pump | Model | / | BW160 | ||

| Max.Displacement | L/min | 160 | |||

| Max.Pressure | MPa | 10 | |||

| Overall Dimensions(L×W×H) | Working Dimensions | mm | 4800×2420×9200 | ||

| Transport Dimensions | mm | 5500×2200×2450 | |||

| Orifice Clamp | Applicable Rods | mm | BQ,NQ,HQ,PQ | ||

| Via Diameter | mm | Φ154 | |||

| Traveling Speed | km/h | 1.5-2.5 | |||

| Climbing Capacity | ° | ≤30 | |||

| Earth Contact Pressure Ratio | MPa | 0.14 | |||

| Weight of Main Machine | t | Con | |||

The hydraulic chuck-type power head facilitates the extraction of the drill pipe. It reduces the probability of collapse and falling of the bottom of the hole, repeated breakage of the drill bit, and core blockage. The coring rate is high.

Wireless walking device can be installed optionally.

Construction Cases

Please contact us for more services and best prices

.jpg)