XDX-2 Hydraulic core drilling rig

XDX-2A full hydraulic core drill rig is mainly used in core drill with diamond bit or hard tungsten-carbide tipped bit in the field of industriesl such as geology, metallurgy, coal, nuclear industry, hydrology, etc.

Main Structural Features:

- The rig adopts full hydraulic driving system and a crawler chassis.

- Drill head adopts top drive structure, with speed adjustment. lateral translation function and two gear stepless

- The rotation of drill head is driven by variable motor, with high working efficiency.

- Mast is foldable, with adjustable leg supports at the lower part, and the upper mast could be equipped with extension joints as needed.

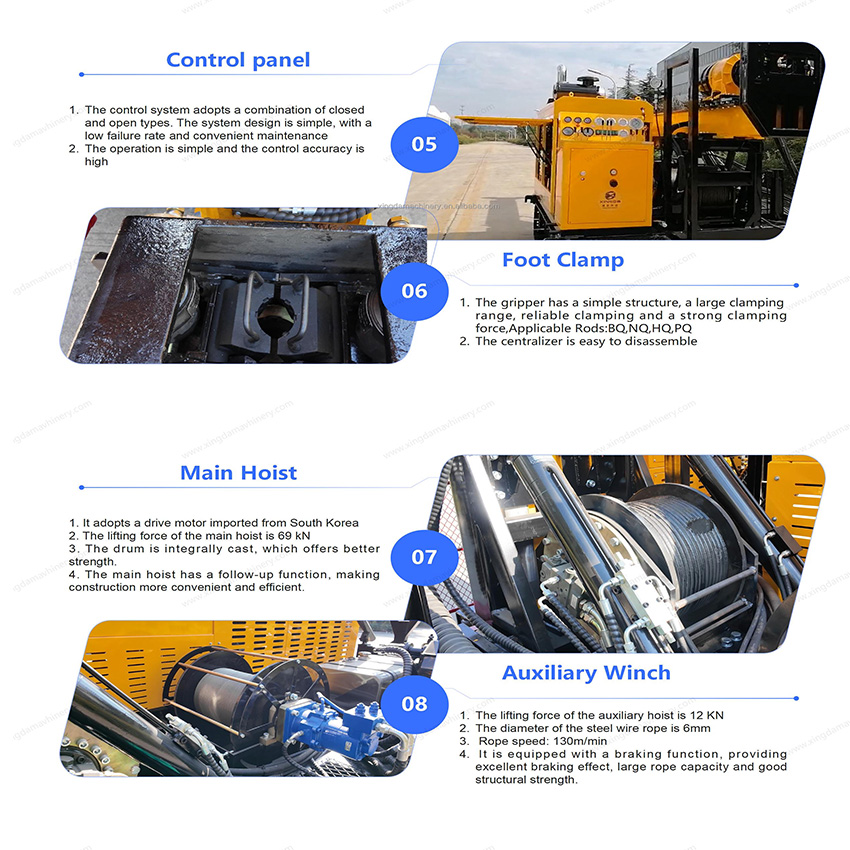

- A hydraulic clamp with a stabilizer is adopted at the position above the drilling hole.

Main parts and auxiliary equipment, including engines, diesel engines, hydraulic pumps,gear reducers,some key valves and hydraulic accessories, are well-known brand products.

SO, the failure rate is low and the maintenance is convenient.

Ⅱ. Main Technical Features:

1. Full Hydraulic and Drill Head model. The drill head rotation is realized with four hydraulic pumps driven by diesel engine; this also makes the feeding hydraulic cylinder system realize its full stroke feeding in both higher and lower speed.

2. The rig can be applied and performed in narrow space for drilling of hole of 45-90° with stronger adaptability.

3. Strong techniques adaptability. Besides diamond drilling with wire line coring technique, it is in strong techniques adaptability. It is applicable for the drilling and feeding requirement of any other stratum.

Ⅱ. Main Parameters

The figures in these tables have been calculated, based on field experiences, and may be reasonably expected.

Actual drilling capacity will depend on in-hold tools and conditions, drilling techniques and equipment used.

| Model / Item | Unit | XDX-2A | |||

| Drilling Depth | BQ Rod(φ55.6mm) | m | 500 | ||

| NQ Rod(φ69.9mm) | 350 | ||||

| HQ Rod(φ88.9mm) | 120 | ||||

| PQ Rod(φ114.3mm) | – | ||||

| Drill Head Capacity | Speed Range | Grade I | r/min | 405-874 | |

| Grade II | 560-1200 | ||||

| Corresponding Torque | Grade I | N.m | 900-425 | ||

| Grade II | 630-293 | ||||

| Max.Rotary Speed | r/min | 1200 | |||

| Max.Torque | N ·m | 900 | |||

| Hole Diameter of Spindle | mm | TDS (Top Drive) | |||

| Max.Lifting Capacity | kN | 50 | |||

| Max.Feeding Power | 25 | ||||

| Translational Distance | mm | 265 | |||

| Diesel Engine | Rated Power | kW | 74(Cummins 4BTA3.9-C100) | ||

| Rated Speed | r/min | 2200 | |||

| Hydraulic Pump | Pump 1 | Rated Pressure | MPa | 22 | |

| Max.Flow | L/min | 156 | |||

| Pump2 | Rated Pressure | MPa | 20 | ||

| Max.Flow | L/min | 40 | |||

| Pump3 | Rated Pressure | MPa | 20 | ||

| Max.Flow | L/min | 13 | |||

| Mast | Total Height | m | 6 | ||

| Adjusting Angle | ° | 0~90 | |||

| Drilling Angle | 45~90 | ||||

| Feeding Stroke | mm | 1800 | |||

| Sliding Distance of Mast | 715 | ||||

| Main Hoist | Single-wire Hoisting Capacity | kN | 20 | ||

| Lifting Speed | m/min | 84 | |||

| Dia.Of Steel Rope | mm | 14 | |||

| Length of Steel Rope | m | 30 | |||

| Auxiliary Winch | Single-wire Hoisting Capacity | kN | 8 | ||

| Lifting Speed | m/min | 96 | |||

| Dia.Of Steel Rope | mm | 6 | |||

| Length of Steel Rope | m | 500 | |||

Mud Pump | Model | / | BW100 | ||

| Max.Displacement | L/min | 100 | |||

| Max.Pressure | MPa | 6 | |||

| Overall Dimensions(L×W×H) | Working Dimensions | mm | 4100×1840×6000 | ||

| Transport Dimensions | 4200×1840×2400 | ||||

Orifice Clamp | Applicable Rods | BQ,NQ,HQ,,PQ | |||

| Via Diameter | Φ124 | ||||

| Traveling Speed | km/h | 1.5-2.5 | |||

| Climbing Capacity | ° | ≤30 | |||

| Earth Contact Pressure Ratio | MPa | 0.14 | |||

| Weight of Main Machine | t | 5.5 | |||

The hydraulic chuck-type power head facilitates the extraction of the drill pipe. It reduces the probability of collapse and falling of the bottom of the hole, repeated breakage of the drill bit, and core blockage. The coring rate is high.

Wireless walking device can be installed optionally.

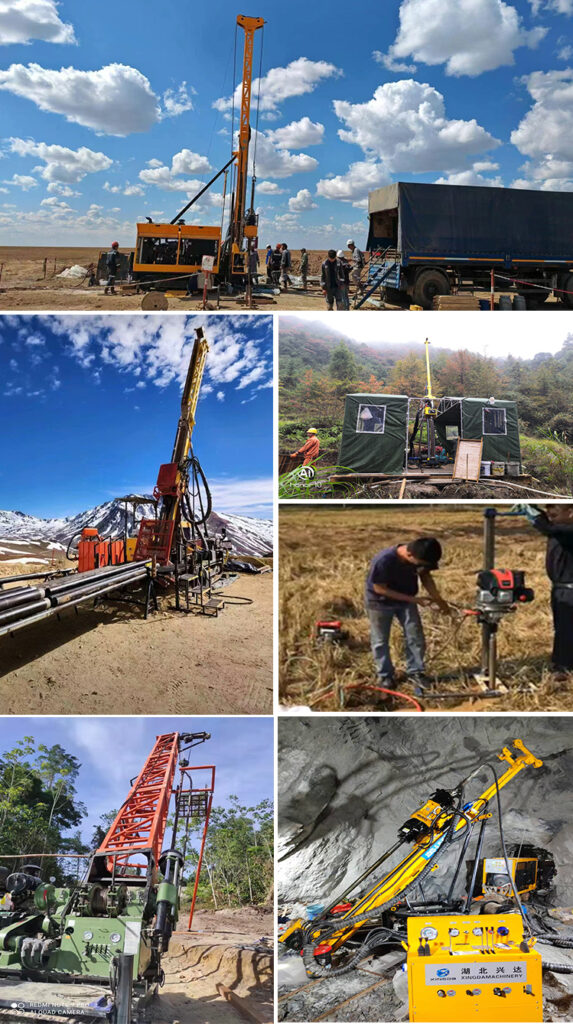

Constuction Cases

We have several models for you to choose from.

They can all meet your different diameters and depths for exploration.

.jpg)